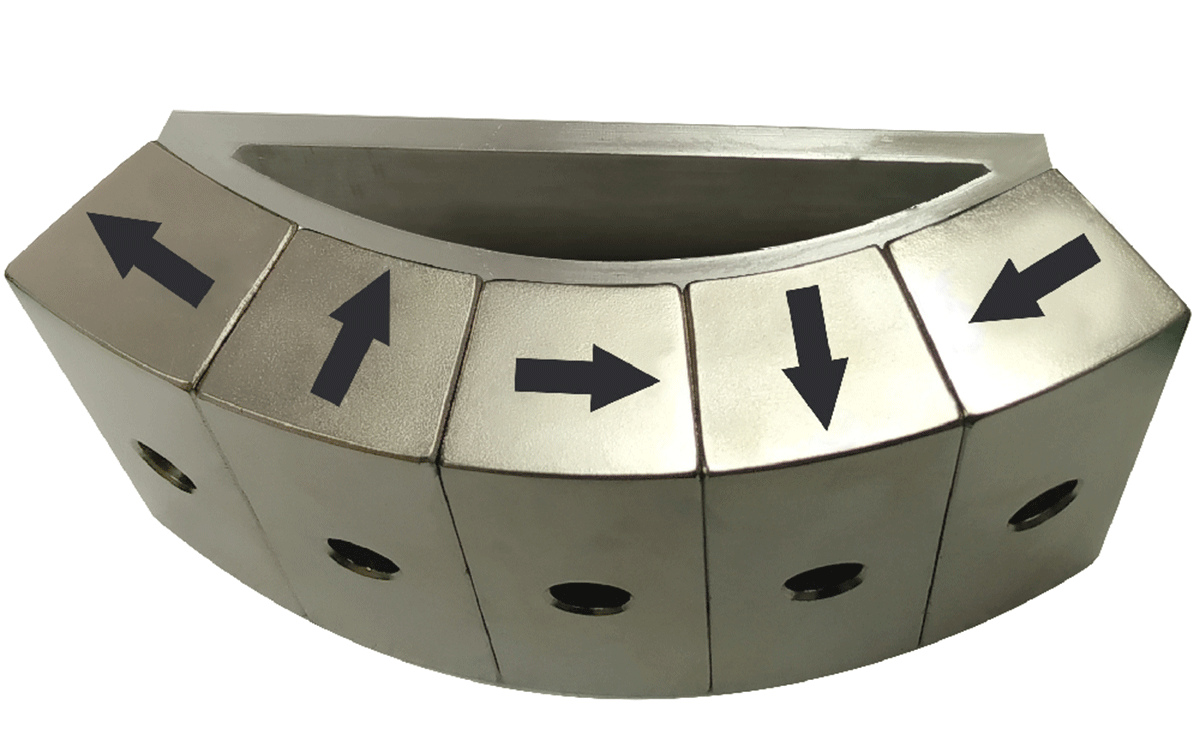

Permanent Magnet Rotor Assembly

The main types of magnets used in magnetic motors include sintered NdFeB magnets, molded NdFeB magnets, injection molding magnets, and ferrite magnets.

It should be noted that the application of different types of magnets in motors is not absolute, and the specific selection should be comprehensively considered according to factors such as the working conditions of the motor, performance requirements, and manufacturing costs.

Sintered NdFeB magnets

Sintered NdFeB magnets are currently one of the most widely used magnet materials, with the advantages of high magnetic energy product, high magnetic permeability and high stability. It is mainly used in high-efficiency and high-performance motors such as permanent magnet synchronous motors, stepper motors, and brushless DC motors.

Molded Bonded NdFeB magnet

Molded Bonded NdFeB magnet is a common magnet material with high magnetic energy product and good magnetic permeability. It is suitable for use in various motor types, especially in medium and low power motors such as DC motors, AC motors and motors.

Injection Bonded magnet

Injection Bonded magnet is a magnetic material made by thermoplastic injection molding, which has excellent oxidation resistance, low temperature coefficient and high magnetic permeability. It is suitable for fields such as low-power motors and precision instruments, such as electronic motors, aerospace devices, and medical equipment.

Ferrite magnet

Ferrite magnet is a commonly used magnetic material with high magnetic permeability and low magnetic energy product. It is suitable for low-frequency motors, high-power motors and large generators, such as power equipment, rail transit and automobiles.